WISFAC

Wafer Inspection Equipment System

Various wafer defects can be detected during the wafer process.

We continue to increase the probability of defect detection by applying superior defect detection algorithms.

1. Air Pocket Inspection

Learn more

IIM-3020 | IIM-3010 | IIM-2010

2. Edge/Surface Inspection

Learn more

ESIS-3000 | EIS-3000

3. Other

Learn more3-1. Final Sorter

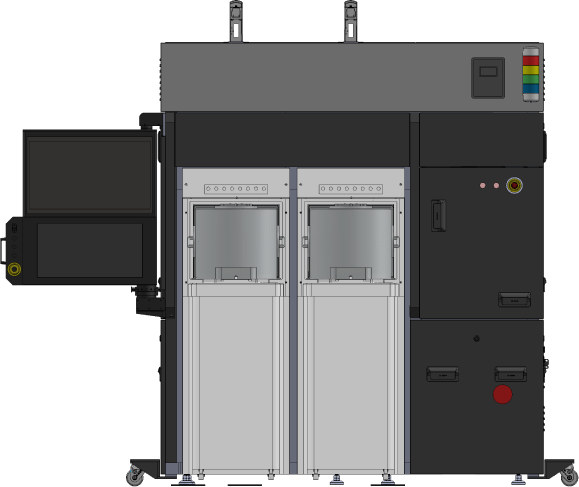

Invert wafers by applying 8 Load Port, 7 Load Port-1F, 4/2 Load Port IWS-3000-8L (8 Load Port) and IWS-3000-7L1F (1 flip-per out of 7 Load Port) inverting robots. Open Cassette, FOSB, and FOUP are all available, and the carrier types (Open, FOSB, and FOUP) used can be automatically distinguished as follows Prevent operator error.

IWS-3000(8Load Port) | IWS-3000(7Load Port 1Flipper) | IMS-3000(4Load Port) | IMS-3000(2Load Port)

3-2. Cu-haze, Edge/DSOD, Edge/Cu-haze

The CHAC-3000, EDIS-3000, and ECIS-3000 are equipment for detecting Si Wafer's Edge defects and Surface Patterns Crystal Originated Pits (COP), and haze pattern.

CHAC-3000 | EDIS-3000 | ECIS-3000